The benefits of using severe buckets out of Hardox 450

Severe buckets out of Hardox 450 offer a number of benefits for businesses, including: Increased durability and lifespan: Hardox 450 is a high-strength and wear-resistant steel

Hardox® Steel’s value-Made to Last

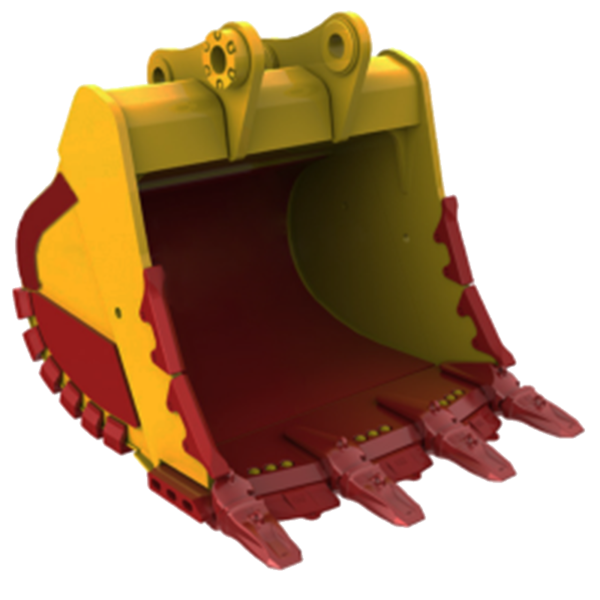

![]()

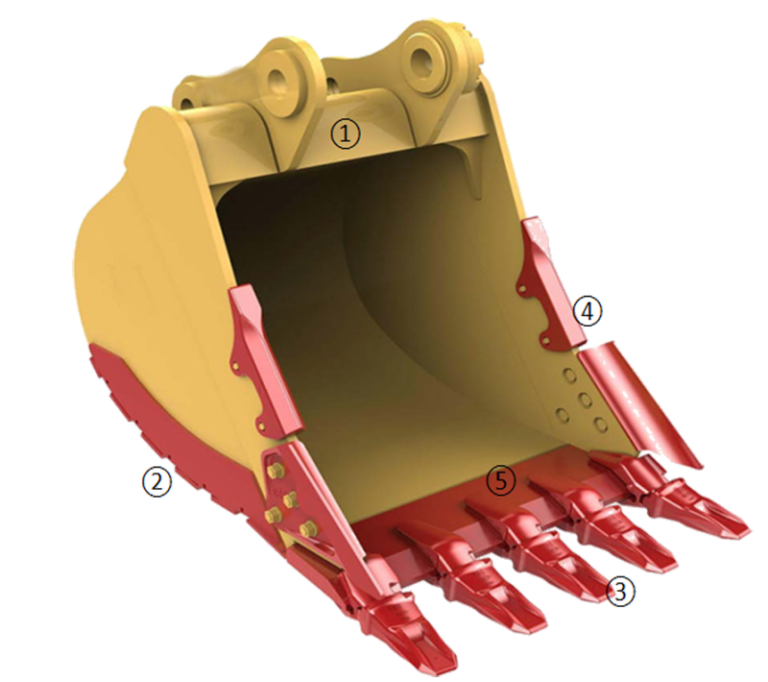

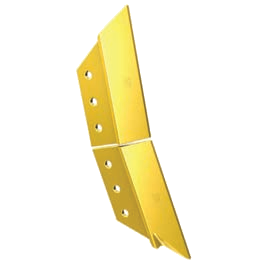

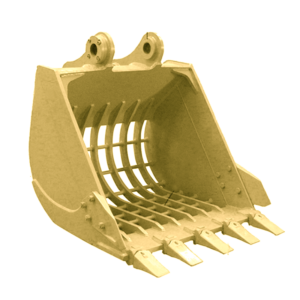

① Optimized Hinge Plates reinforced construction for high strength and performance

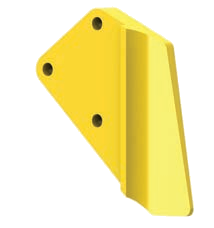

② High strength steel Side Plates with bottom wear plates for corner protection

③ Forged Teeth from steel with properties that maintain hardness for long wear life in tough digging applications

④ Side cutters & Pre-Drilled Sidebar Protectors For Protection And Penetration

⑤ Hardox® Wear Plate Straight Or Spade Base Edge depending on application

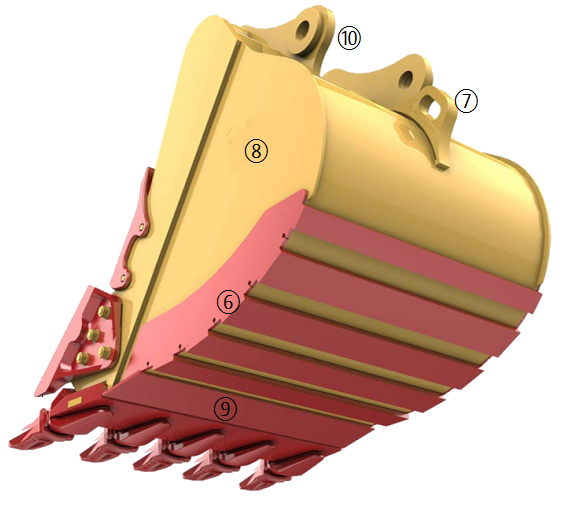

⑥ Horizontal Bottom Wear Plates Protects Wrapper Area And Reinforces Bucket For Greater Strength And Rigidity

⑦ Larger Loop And Thinner Lift Eye Design For Easy Shackle Matching

⑧ High-Strength, Quenched And Tempered Steel

⑨ Hardox® 450 Brinell Wear Plate, High-Strength, Abrasion & Resistant Steel

⑩ Compatible With All Poplular Excavators Mounting Including Caterpillar, Case, Doosan, Hitachi, Hyundai, John Deere, Kobelco, Komatsu, Liebherr, Link-Belt, And Volvo, To Name A Few.

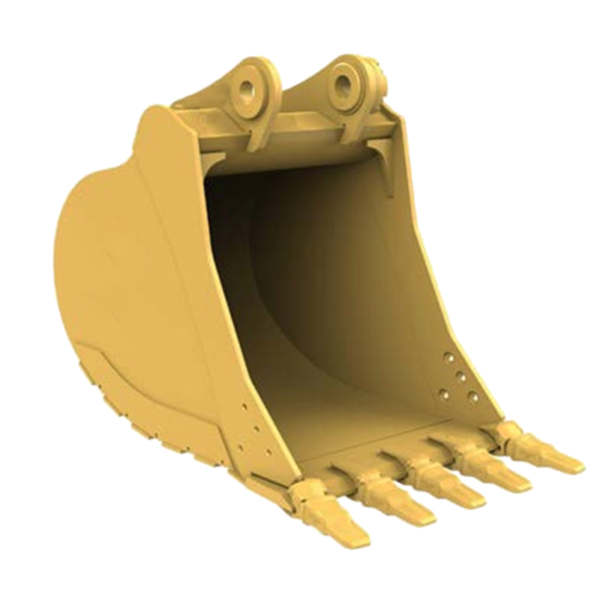

For digging in low impact, lower abrasion

materials such as dirt, loam, and mixed

compositions of dirt and fine gravel.

Applicable for excavators from 8 to 45 tons.

1.Hardox®wear plate cutting edge.

Lighter structures decrease load time

and increase the weight that can be lifted.

2.Standard size replaceable adapters and teeth.

3.Side cutters and sidebar protectors are pre-drilled for optional choice.

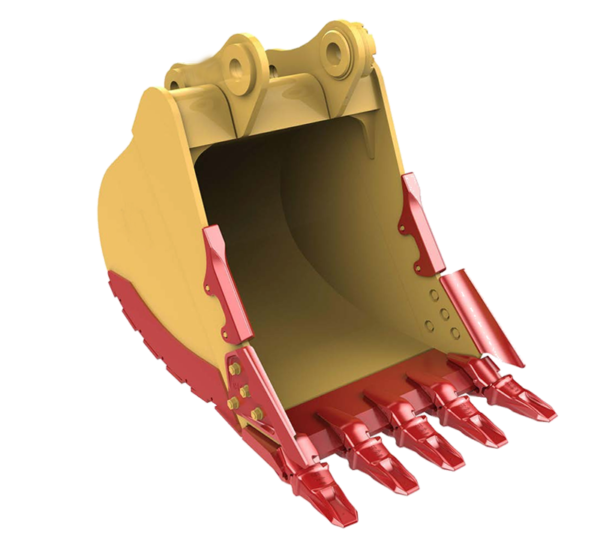

For a wide range of impact and abrasion

conditions including mixed dirt, clay and

gravel rock.

Applicable for excavators from 18 to 90 tons.

1.Adding Hardox®wear plate bottom and side wear plates than General Duty Buckets for more durability.

2.Buckets Adapters and teeth are up sized for enhanced performance and durability.

3.Sidebars protectors & side cutters are are installed as standard.

For higher wear conditions, such as excavation of hard rocks, sub-hard rocks, and weathered rocks mixed in the soil; heavy-duty operations such as loading of hard rocks and ore after blasting.

Applicable for excavators from 18 to 200 tons.

1.Bottom Hardox®wear plates are about 50% thicker than Heavy Duty Buckets.

2.Side Hardox® wear plates are about 40%

larger than Heavy Duty Buckets

& additional Corner Shrouds for

added protection against abrasive and

gouging wear.

3.Adapters and teeth are sized to

accommodate higher loads and abrasion conditions.

For very high abrasion conditions

including high quartzite granite.

1.Extreme Duty Buckets are armored

with extra protection from abrasion and

gouging wear. They include: Corner

Shrouds, Sidebar Protectors with

Shear Blocks, Additional Wear

Material on the side, and Base

Edge End Protectors.

2.Even more protection is available

for buckets on larger excavators include: Liners, Base Edge Segments.

Side wear plates are larger; and

Adapters and teeth are sized to

accommodate higher loads and

abrasion conditions.

Choosing the right GET is important to getting the highest return on your investment.Ground Engaging Tools protect the expensive parts of your buckets and the resulting longer life reduces your maintenance costs. GET also play a big part in determining how well your bucket performs in a specific application.

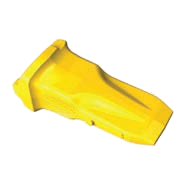

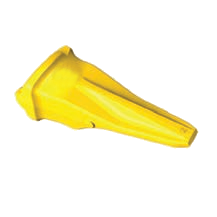

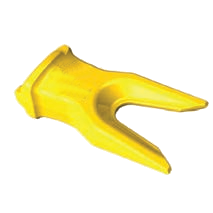

Recommended for most excavator applications including high impact trenching, excavation and loading. Good penetration. Stays sharp

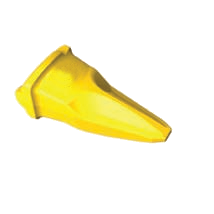

Recommended for harder-to-penetrate, moderate impact, lower abrasive materials. Very good penetration, less wear material, stays sharp.

Recommended for maximum penetration, especially in cohesive materials. Excellent penetration, less wear material, stays sharp. (Use Double Spike in corners.)

Recommended for harder-to-penetrate, fracturable materials. Very good penetration, stays sharp. Use in corner positions with Spike centers.

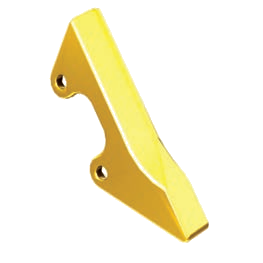

Protects sidebars from wear and damage. Pins on for easy removal and installation. Can be stacked, one above the other on the side of the bucket for more protection.

For tough digging conditions. More wear material. Covers more of sidebar for enhanced protection of the bucket. Scalloped profile improves bucket penetration and machine performance.

Effective in moderate-impact conditions. Suitable for most soil conditions. Provides a strong, wear-resistant surface to help protect bucket sides. Extends bucket side width to match the teeth bite.

Half-arrow shaped to provide better penetration than bare bucket, while protecting the lower bucket sides and corners. Use in moderate-to-light conditions. Can be stacked for more protection.

Several different Bucket styles are available — each with a special purpose.

These buckets are designed for cleaning ditches, sloping, grading and other finish work. Their shallow depth and compact size make working in confined areas easier. Drainage holes allow liquid to empty so material dumps more easily.

Excavator tilting bucket really increase productivity because they provide up to 45 degrees slope left or right. When sloping, trenching, grading, or ditch cleaning, control is fast and positive, so you get the right slope on the first cut.

The wide opening width is light in weight, which maximizes the operating efficiency and is light in weight.

Clamshell bucket is best for dredging and material re-handling. Regardless of the versions, these equipment pieces feature a 360-degree sealed rotation. Recommended Application: commonly used in dredging, excavation, or material handling.

Excavator skeleton bucket is great for sifting out rocks in soil, effectively mining and sorting rock and removing other debris without the soil. It is available in many different sizes, widths, and even custom rib spacing configurations, too.

We have a wealthy selection of attachment products to match your different equipment and work needs. All attachments are made by us with years of research and development and supply chain management optimization, so you are in the right place to select the best quality and cost-effective attachment products.

Our attachments are durable, cost-effective, versatile. Faith Equipment delivers the performance, comfort and power to take on the most challenging projects, helping customers work faster and smarter.

Severe buckets out of Hardox 450 offer a number of benefits for businesses, including: Increased durability and lifespan: Hardox 450 is a high-strength and wear-resistant steel

Severe buckets are designed to handle a variety of tough rock materials, including: Granite Shot rock Aggregate Coal Recycled concrete Other abrasive materials commonly encountered

Yes, it is true that severe duty buckets are more popular than heavy duty buckets and general purpose buckets. This is because severe duty buckets

The most popular steel plates for severe buckets are: Hardox 450 is a high-strength, wear-resistant steel that is ideal for severe-duty applications. It has a Brinell